How does BMS Boost the Battery life and Performance?

How does BMS Boost the Battery life and Performance?

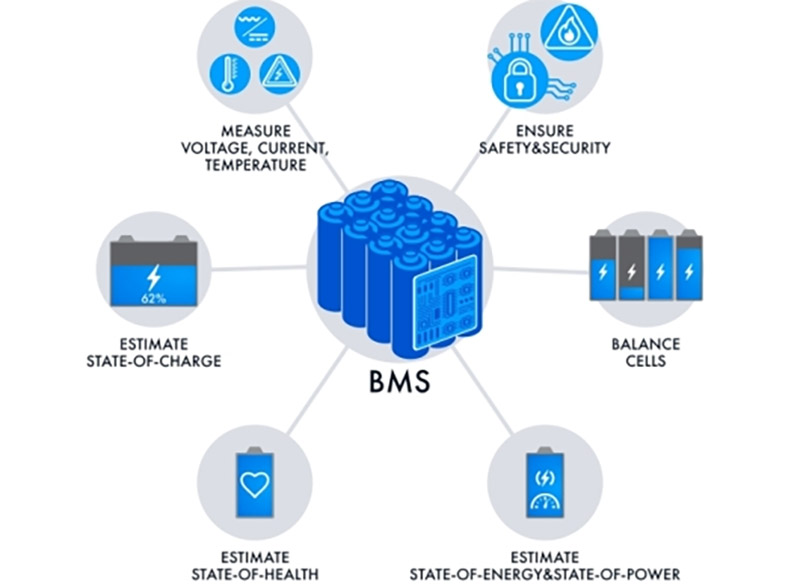

BMS tasks include voltage and current control, thermal management solutions, fire protection, and cybersecurity. In this article, we explain the main battery-related risks and ways that BMS can overcome them.

BATTERY PROTECTION WITH A BMS

A rechargeable battery is a keystone of a BMS. This component is rather complicated and sensitive and requires attention and careful handling. A BMS can do this. All its functions intend to make the most out of the battery in the longest possible time.

Thus, by checking the state of charge and state of health, a BMS can boost the battery life and its performance. By estimating the state of energy and state of power and balancing cells inside a battery pack, it can use the full potential of the battery and, as a result, your battery energy storage system.

Depending on the composition, batteries can be rather sensitive to an unstable surrounding. Exceeding the limits can be critical for a battery and may cause its come-down and early death.Moreover, a battery’s crush can cause harm to its user. For example, lithium-based batteries are infamous for their inflammability and explosiveness in some cases.

Fully equipped, a BMS can predict potential hazards and protect both the battery and the user. A well-developed BMS has battery safety systems that prevent short-circuits, ground faults, and thermal runaway. Thus, a BMS security system provides safe data transfer and defends your battery storage system from unsanctioned usage.

A BMS with a real-time operating system reacts to all changes or threats immediately, so it helps to avoid early battery replacement and expensive repair.

In this article, we pay special attention to a lithium-ion (Li-ion) battery. This type of battery requires careful handling, as it is sensitive to extreme temperatures, overcharging, and constant lack of charging. A BMS can provide such treatment.

VOLTAGE & CURRENT CONTROL

To control the battery’s current and voltage, you have to provide overcurrent and overvoltage protection while charging and avoid undervoltage while discharging the battery.

- The challenge: Every battery type has suggested current and voltage

limits for charging and discharging. Exceeding these parameters can lead to oxidation and a short-circuit that can damage the battery and shorten its lifetime. In the worst case, it might be an explosion, fire, and electric shock.

- Recommended actions: Adding enough sensors to the cells allows a

BMS to have data and analyze it for further actions.

As a result, the system can control the current, voltage, and state of charge, which correlates to voltage. In case of deviations from the permissible values, the BMS can use a breaker to disconnect the circuit and stop charging the battery.

BMS can warn users about the battery’s possible problems. In this case, the system will send an alarm or push notification and display it on the panel of the device.

BMS, as well as chargers, can use a constant-voltage/constant-current battery-charging method to carry out overcurrent and overvoltage protection. The idea is as follows:

You charge the battery with a constant current until the battery reaches a certain voltage level. Then you charge the battery with constant voltage while the current drops. Charging is over when the current has the lowest possible value.

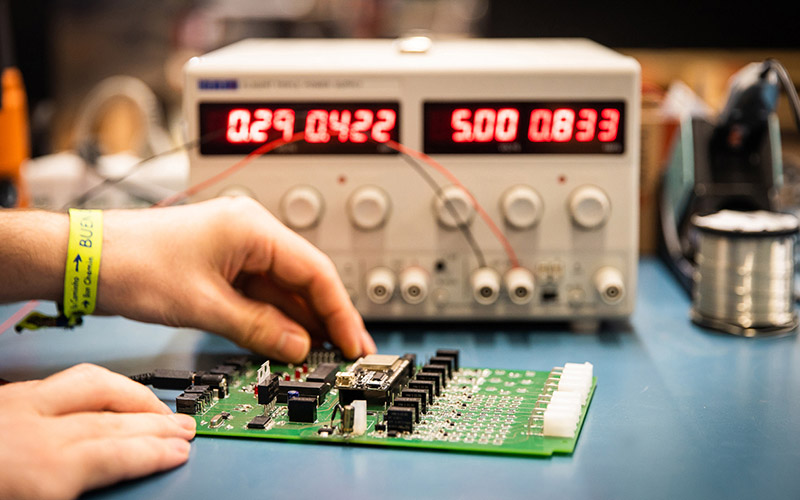

You can install voltage and current monitoring at both the software and hardware level of your BMS. Here are examples of the basic hardware we used for an industrial BMS solution:

- Current and voltage transformers

- An amplifier and a buffer with a resistive divider for increasing the value of the output current and voltage

- An analog-to-digital converter that converts the current and voltage values to digital signals

- A microcontroller (MCU) for reading signals

When designing protection circuits, you have to be careful. Extra electronics can not only increase the BMS cost but also increase internal resistance and reduce the power of the battery.

THERMAL MANAGEMENT

Thermal management is one of the most important Li-ion battery safety precautions for BMS. It includes battery temperature control and deals with heating, cooling, and air conditioning

- The challenge: Efficient Li-ion batteries are vulnerable. Lithium is a

very reactive and flammable metal that can flame up in a flash when it comes into contact with water and air.

Even a minor increase in temperature or slight damage to the battery can cause thermal runaway and short-circuit, leading to explosion and fire.

That’s why battery thermal management is extremely important for Li-ion–based solutions. Acceptable temperatures for batteries are:

32˚F to 113˚F (0˚C to 45˚C) for charging

–4˚F to 140˚F (–20˚C to 60˚C) for discharging

32˚F to 68˚F (0˚C to 20˚C) for storing

- Recommended actions: Your BMS’s battery thermal management

system can check that the temperature is within the limits. To measure the temperature in and around the battery, you can use temperature sensors or thermistors — semiconductor thermal resistors.

A BMS finds out deviations from certain values and takes immediate actions to save the battery.

For instance, a BMS can apply thermistors and thermal fuses to protect the battery from overheating during work. They will open the circuit and disconnect the battery if the temperature rises too high.

Most up-to-date BMS use negative temperature coefficient (NTC) thermistors. They are very receptive and can detect any changes in resistance with high speed and accuracy.

A thermal BMS focuses attention on lithium batteries while charging and discharging. First and foremost, it should track the temperature of the battery inside to protect it from thermal runaway and ignition.

Furthermore, it has to protect the battery against unfavorable environmental conditions. Li-ion batteries are very sensitive to temperature drops. You should charge or discharge them at a specific temperature. Exceeding limits may result in battery senescence, loss of power, and complete halting.

A thermal management system responds to any emergency. It adjusts the temperature or turns off the charger using battery cooling; fans; or heating, ventilation, and air conditioning (HVAC) systems.

Another feature implemented in BMS is heat dissipation. The system uses it to remove excess heat generated by electrochemical reactions in a battery. The method includes air and liquid cooling and convection.

Besides the battery, you need to secure the thermal management of electronics involved in your BMS solution. A proper number of thermistors and thermostats can defend both the system and the user from potential thermal hazards.

FIRE PROTECTION

The chances of fire happening are low, but sometimes the worst happens. In case of battery inflammation, the system should alert you immediately and take the necessary steps to cut it short. If you cannot avoid battery overheating, make sure your BMS has a fire-protection system.

- The Challenge: Fire is one of the most serious menaces for a lithium

BESS.That is why you have to keep in mind the flammability of this technology and take all needed actions to prevent possible problems.

Yet your battery can catch fire due to manufacturing defects.

The flaws in cell packages and battery plates can cause internal short-circuits that lead to sparks, smoke, and flames.

- Recommended actions: It would be good to check a battery for

factory defects before usage. It has to be a detailed examination of the battery and its package, components, and construction.

Correct installation, usage, maintenance, and storage can also diminish the risk of battery fire. Acting within current, voltage, and temperature restrictions can prevent your Li-ion battery from overheating and ignition.

You can protect yourself and your BMS from smoke, fire, and toxic gases by establishing a reliable fire-protection system.

Smoke detectors can solve the problem. Using a BMS can promptly detect battery combustion and connect to cell-cooling and fire-extinguishing systems.

Methods of fire handling depend on battery size and an ignition scale. Small batteries like phones or laptops need a foam extinguisher or ABC dry chemical to be kept around for fire protection. Water is commonly used for larger fires, but it has to be a large amount of running water to cool down the battery and get rid of oxygen created by the battery breaking down.

The more complex the battery system, the more complicated the fire protection it should have.

CYBERSECURITY

Protecting the battery from running out of limits is not the only problem the BMS can solve. Nobody wants their system to suffer from attacks or data being stolen.

- The challenge: A lot of BMS are IoT solutions. Internet connections

enable users to observe and control their systems at a distance. In this case, there is always the risk of compromising the privacy and unity of information. Thus, BMS can also be susceptible to cyberattacks.

The system needs robust BMS security features to resist unauthorized access and malicious acts that can be harmful to the battery and corresponding BMS modules.

- Recommended actions: Secure your system by carrying out diverse

safeguard processes.

First, make sure that only authorized users can access and moderate the system. To do this, you can add a user identification system with unique passwords and/or other authentication approaches.

For data unity and security, your communication protocol should have strong encryption mechanisms. In this way, a BMS can uphold any interactions between the elements while maintaining secrecy about the BMS and its user.

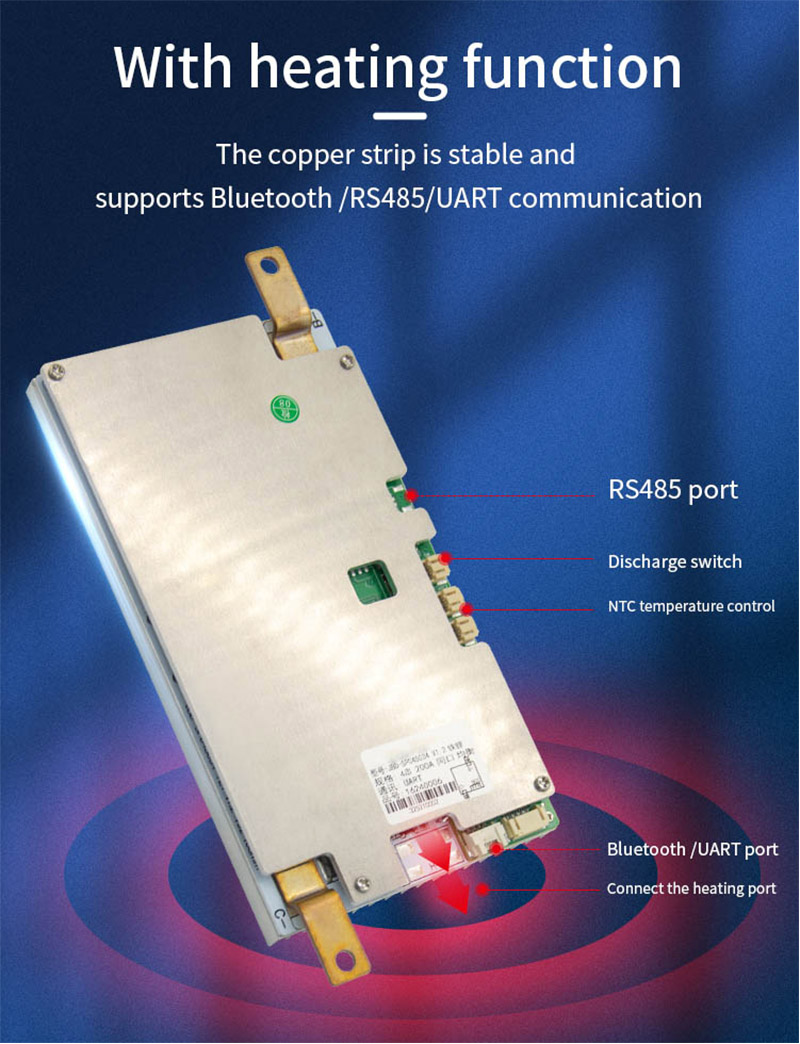

Basen provides DALY BMS and JBD BMS for LiFePO4 batteries and battery packs with strong load capacity, continuous discharge current up to 200A.

● 4 cell series protection

● Various protection functions for charging and discharging

● Discharge over current, short circuit protection functional processes of hardware

● Over voltage, under voltage, temperature and overload protection function processing of software

● Accurate SOC calculation with automatic SOC learning function

● UART/RS485 communication function, can read all data of battery in real time and upgrade online

Have more questions about BMS? Talk to a Basen BMS expert and get all your questions answered now.